RODOLFO COMERIO proudly announces the opening of the COMERIO CALENDERING TECHNOLOGY CENTER, an international center of excellence dedicated to research, development, and experimentation in the industrial calendering sector.

Located in the heart of Italy’s manufacturing district, this center serves as a technological platform of reference for companies, designers, engineers, and researchers from around the world, with the mission to explore and implement sustainable, customized, and high-performance solutions.

A Comprehensive Ecosystem for the Future of Industry

The COMERIO CALENDERING TECHNOLOGY CENTER is the result of a strategic investment and offers an integrated operational environment to develop, test, and validate innovative calendering processes on an industrial scale.

With two complete calendering lines featuring different layouts and the most advanced technologies, the center offers:

- Realistic simulation of production processes

- Real-time data collection for feasibility studies

- Full design support from the RODOLFO COMERIO Technical Department, focused on delivering tailor-made, high-efficiency systems, with particular attention to:

-

- waste reduction and circular economy

- energy efficiency

- quick production changeover

- enhanced industrial performance

-

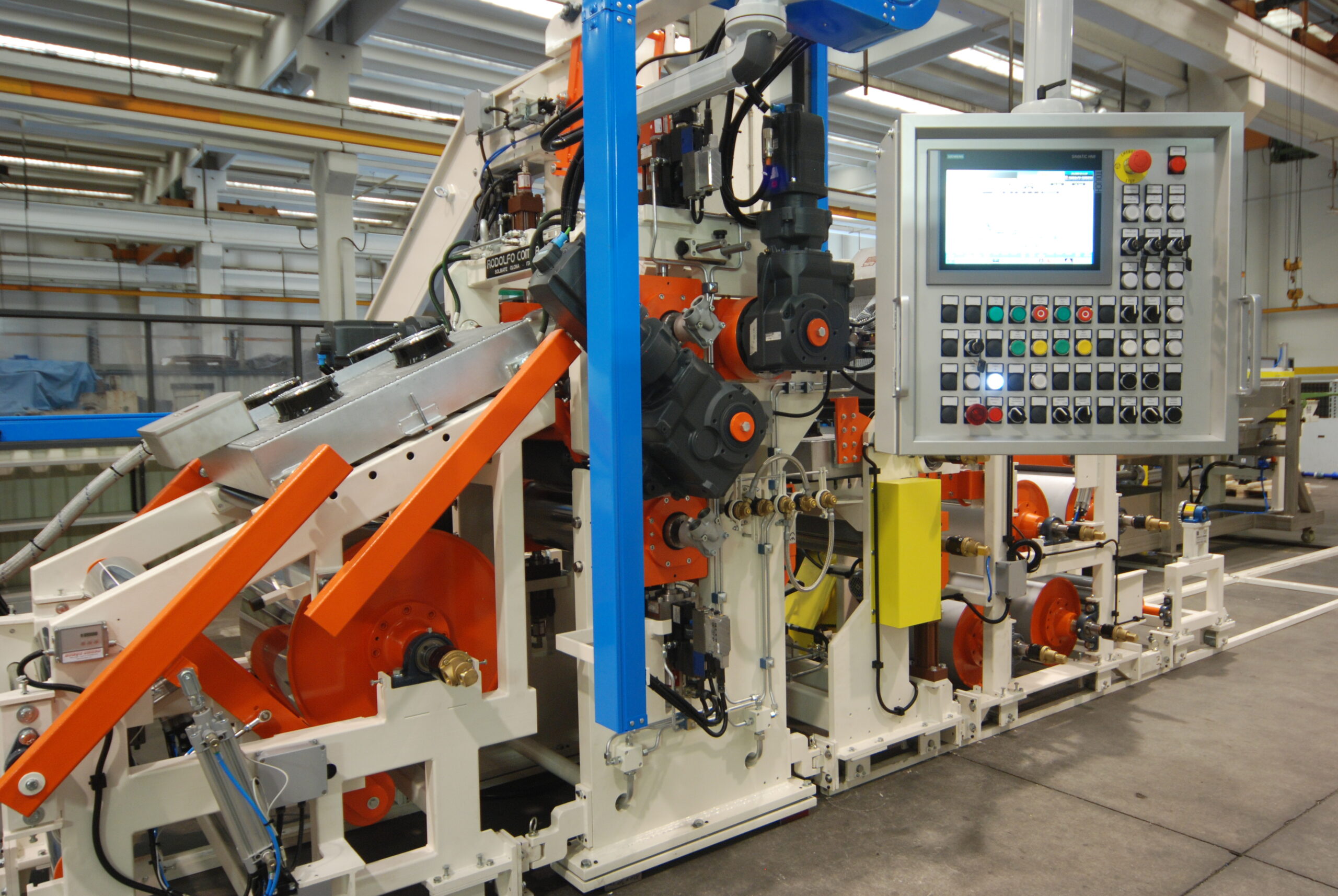

LAB1 – FloorEng: Specialized Line for Resilient Flooring and High-Tech Materials

LAB1 is designed for the production of SPC, LVT, and advanced resilient flooring, handling highly filled polymers and composite materials. Its configuration also supports elastomer calendering and specialized formulations across the automotive, aerospace, and industrial sectors, where precision and performance are essential.

Key specifications:

- Production capacity up to 2000 kg/h

- Maximum film width: 430 mm

- Maximum thickness: 6 mm

- ICMA SG extruder designed for high-filler materials (no turbo mixer required)

- 4-roll calender with patented modular configuration protected by industrial secrecy

- Inline lamination and embossing with technical films (glass, reinforcement, barrier, etc.)

- Integrated system for cooling, plank cutting, stacking, and palletizing

- Double winder for continuous processing

LAB2: A Versatile Line for Multiple Sectors

LAB2 is tailored to meet the needs of flexibility and operational simplicity, making it ideal for a wide range of applications:

- Furniture

- Packaging

- Waterproof membranes

- Conveyor belts

- Tire and automotive sectors

- Special PVC-FREE productions

Technical features:

- Throughput up to 2000 kg/h

- Maximum film width: 430 mm

- Minimum thickness: 0.035 mm

- 4-roll calender – “F” configuration

- Inline lamination with technical films

- Double winder for continuous processing

Processable Plastic and Composite Materials (LAB1 & LAB2)

The center is capable of processing a broad variety of plastic materials, including:

- PVC (Polyvinyl Chloride)

- RPVC (Recycled PVC)

- PP (Polypropylene)

- TPO (Thermoplastic Olefins)

- TPU (Thermoplastic Polyurethanes)

- TPE (Thermoplastic Elastomers)

- ABS (Acrylonitrile Butadiene Styrene)

- Various blends and multilayer materials (e.g. PVC/PU, PVC/EVA, PET/PE)

Processable Elastomeric Materials (LAB1 & LAB2)

The elastomer segment is equally covered:

- NR (Natural Rubber)

- SBR (Styrene Butadiene Rubber)

- EPDM (Ethylene Propylene Diene Monomer)

- NBR (Nitrile Rubber)

- CR (Neoprene)

- IIR (Isobutylene-Isoprene Rubber, Butyl)

- FKM (Fluoroelastomers, e.g., Viton®)

- CSM (Chlorosulfonated Polyethylene)

- VMQ / Silicone (Polysiloxanes)

An International Hub Serving Sustainable Innovation

The COMERIO CALENDERING TECHNOLOGY CENTER stands out as an international hub for innovation, thanks to:

- state-of-the-art technology

- proven industrial know-how

- strong commitment to research collaboration with universities, startups, and global companies

- an ethical and sustainable approach to industrial development

“With this new technology center, we aim to provide companies worldwide with a space where they can test, innovate, and enhance their production processes with a sustainable and data-driven approach,” says the RODOLFO COMERIO Management Team.